Explore our nanolayer technology

Platform Technology

Nanolayer and Microlayer Materials Processing

Our coextrusion technology platform offers polymer processing capabilities to create layered polymer material products. The number of layers in multilayer structure can vary from only a few layers to thousands of layers.

Layer Structure Possibilities

Our coextrusion set-up capabilities include processing of broad range of starting layer structures. The structures can eventually be multiplied to create 100s to 1000s of layers.

-

From 1 to 1000s of layers, capability to go to 10,000+ layers

limited only by the thinnest layers integrity

-

from 1 to 4 number of polymers, can blend other polymers or add additives

-

from 10s to 100s of nanometers up to several 10s of micrometers

-

ability to control relative thickness of the layers

Why are layers beneficial?

Mechanical Properties

Layered structure have demonstrated effect on toughness, delamination, failure properties, ballistic properties, tensile, fatigue and deformation. Coextrusion process can be used to change the phase behavior , crystallization, interfacial interactions, phase dispersion, and blending conditions to alter mechanical properties.

An example below shows effect of number of layers on impact strength of composites.

The graph shows relative impact stretgh (at room temperature) of polycarbonate/styrene-acrylonitrile copolymer, PC/SAN, composites, with varying number of layers and PC content

Gas Transport

Multilayer coextrusion approach has demonstrated nanoscale confinement unlike any other conventional techniques. Our process allows production scale-up to develop next generation packaging materials with controlled gas and moisture barrier properties.

An example of how layer confinement and nanolayering affects oxygen barrier is shown below.

The graph shows effect of layer thickness on oxygen permeability of layered film of polyethylene oxide coextruded with different materials. When PEO thickness is reduced to 10s of nanometers, the lamellar orientation in PEO affects the gas transport properties by two orders of magnitude.

Optical properties

Layered materials are commonly used to create optical filters, nonlinear optically absorbing gilms, lasing films, optically patternable composites. Two colorless polymers with different refractive index can create structural colors, similar to butterfly wing colors.

The image shows a gradient layered structure of PMMA and polyesters and an optical reflection of 448-layered film.

Dielectric properties

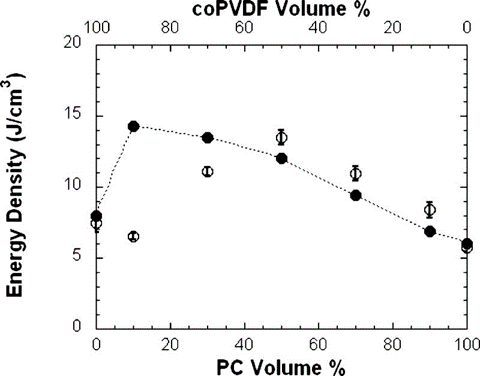

Combination of polymers with different dielectric properties at micro- and nano-scale showed a synergistic effect of improved breakdown strength and reduced losses, leading to high energy density properties.

Coextruded films of PVDF copolymer and Polycarbonate takes advantage of high dielectric permittivity of PVDF and high breakdown strength of PC. When combined in a layer structure, improved energy density could be achieved.

Composite Materials

Nanolayer and microlayer coextrusion allows to combine and control the polymer-polymer interaction at nanoscale. Ability to combine non-conventional polymers with added material design freedom can help you design your next products.